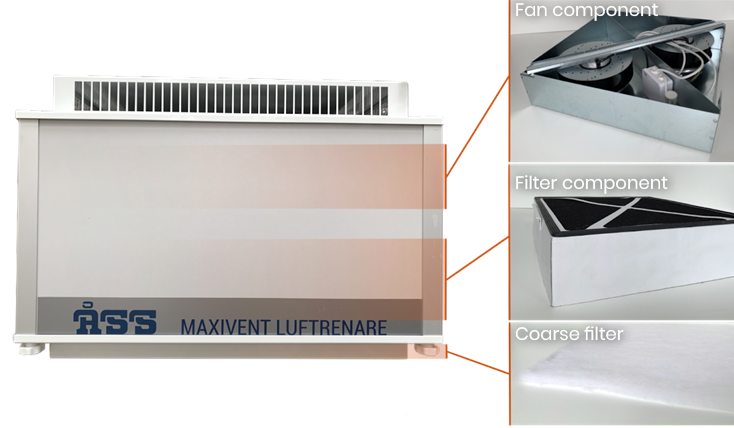

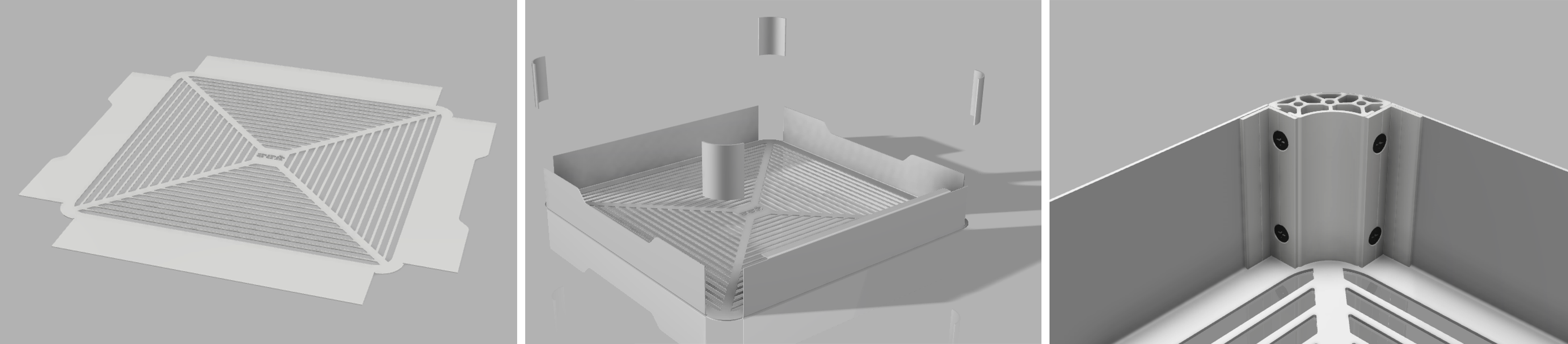

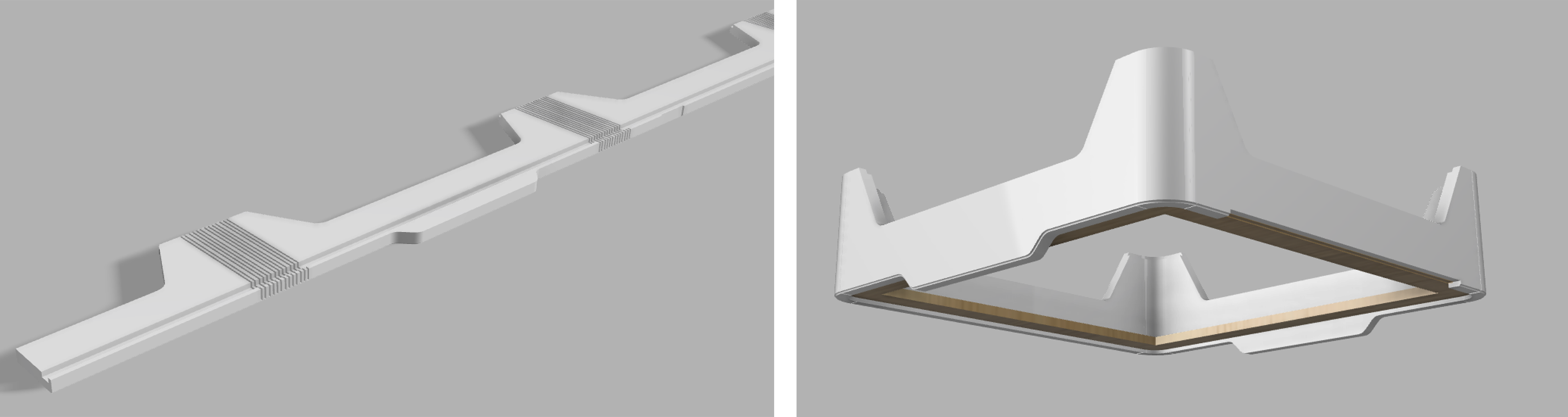

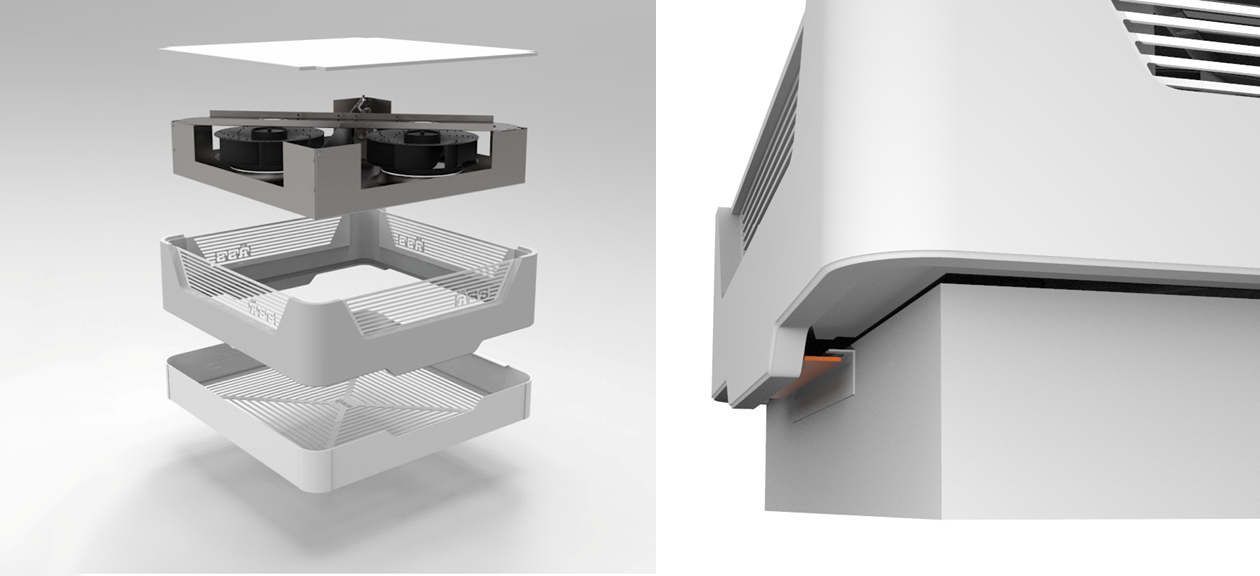

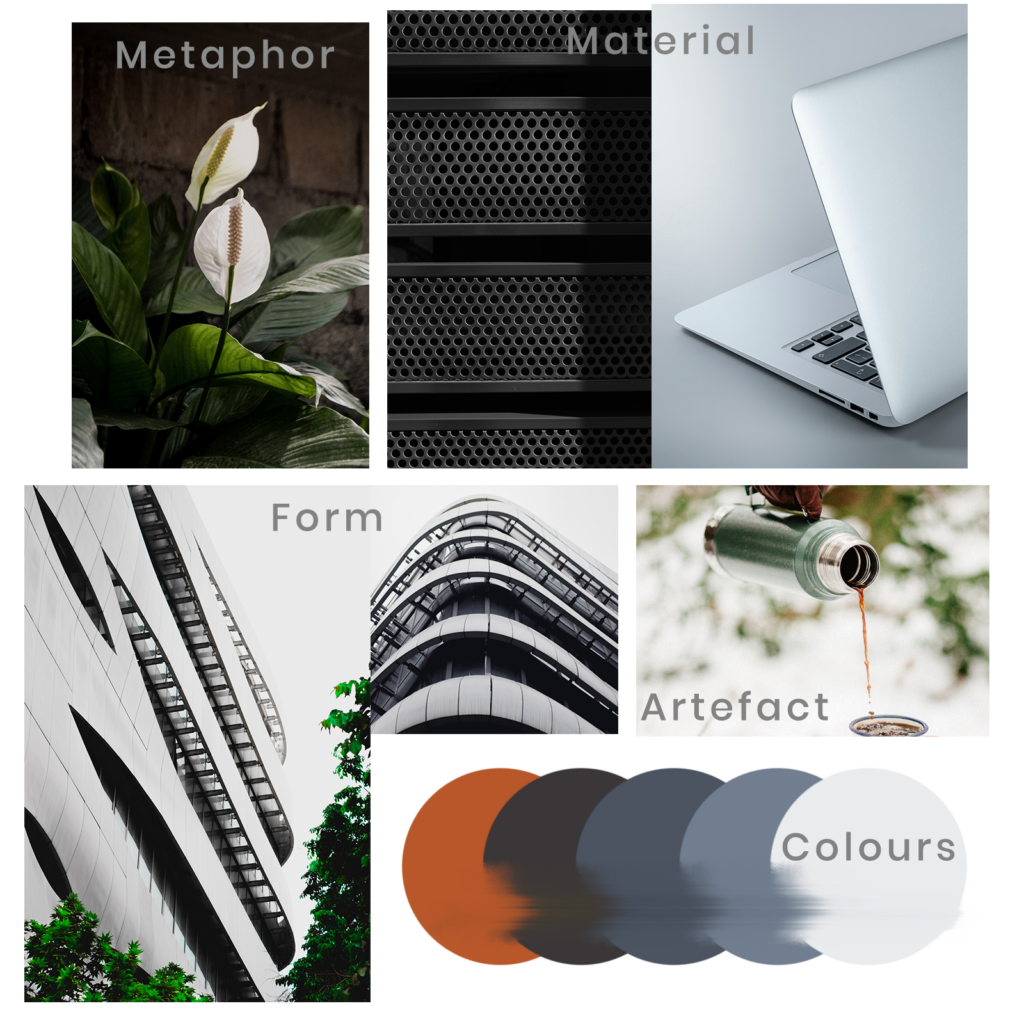

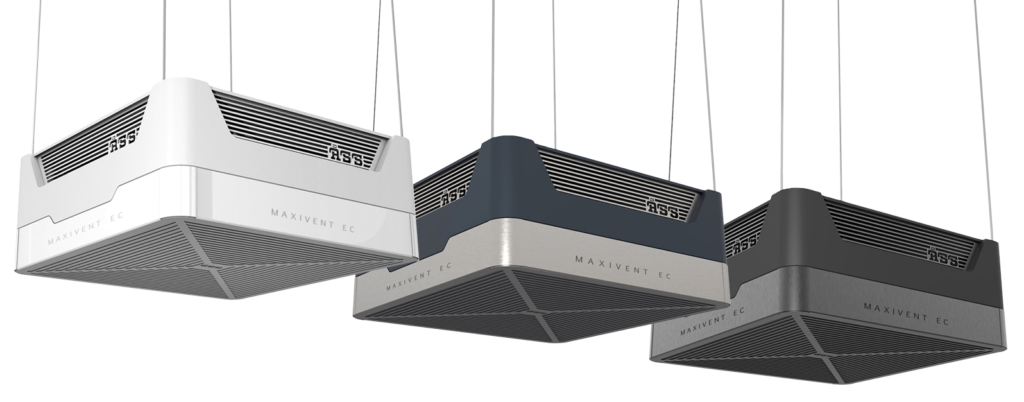

Maxivent Luftrenare is an air purifier made by the company ÅSS Processventilation. It has looked the same since the 90’s when it was released on the market. Maxivent Luftrenare has now been replaced with a newer version called Maxivent EC. Before the release of the new Maxivent EC we had the opportunity to give Maxivent a complete makeover.

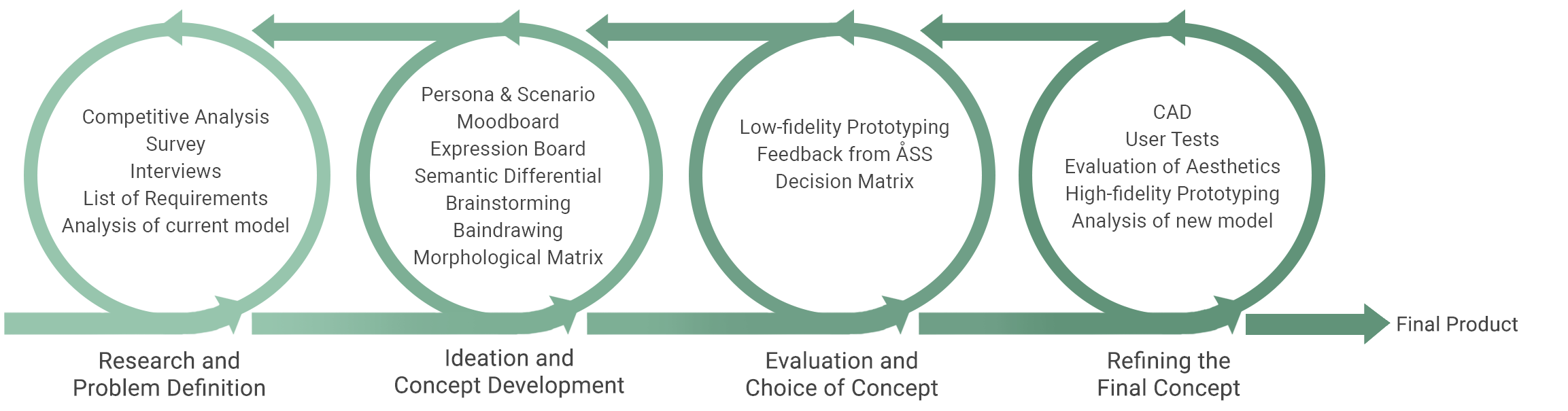

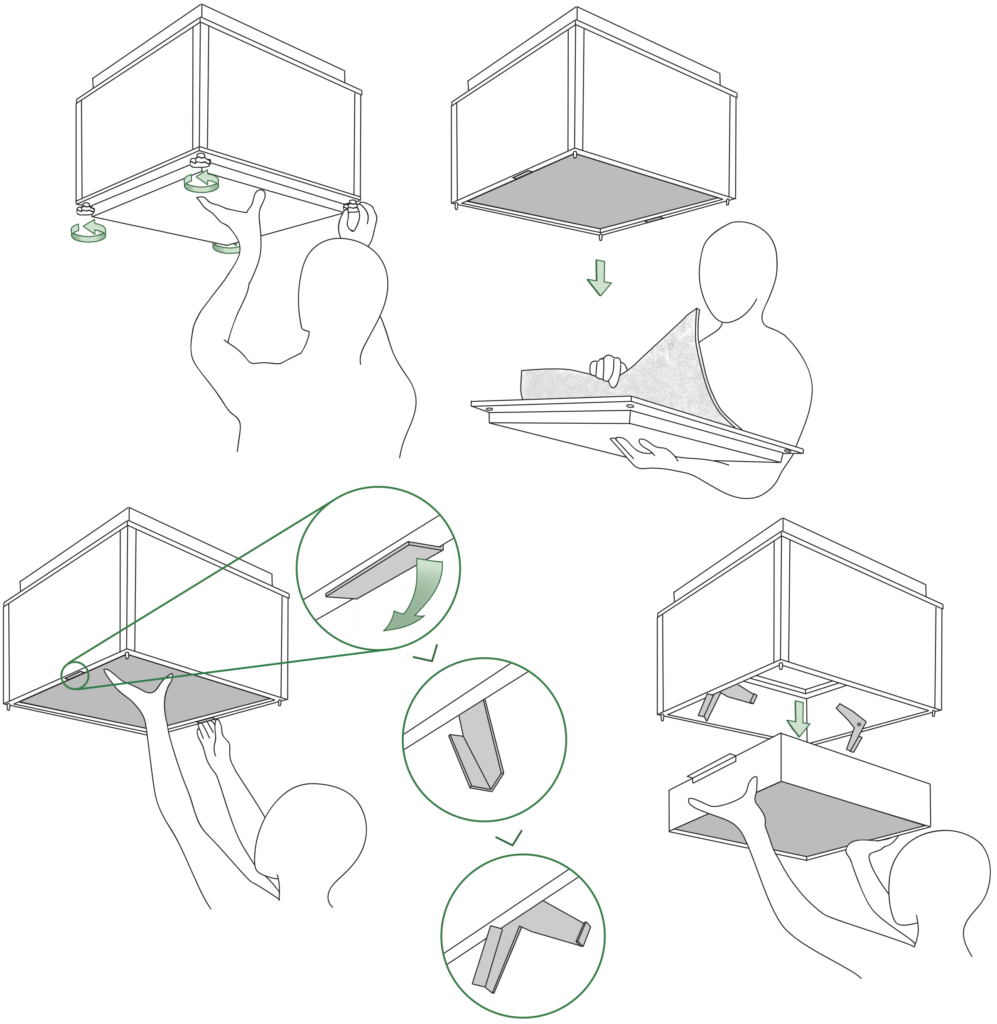

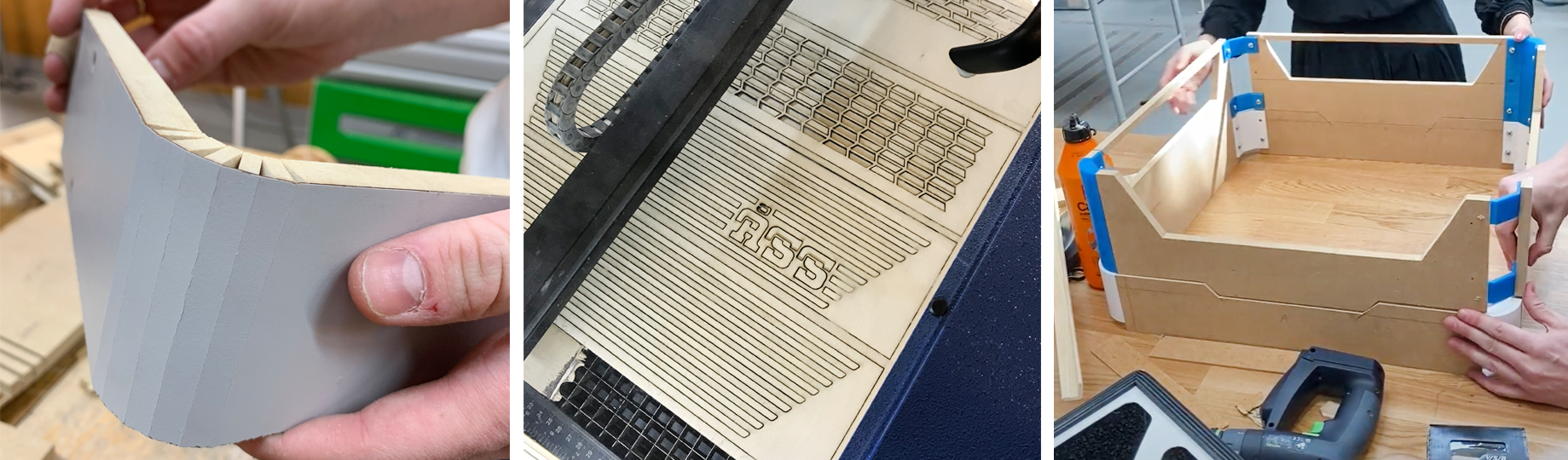

A user-centered design process was applied during the project. Sketches and prototypes were used to test and visualise ideas. The concepts were continuously evaluated together with the company and the users to fulfill needs from both sides. We designed Maxivent EC to fit in a variety of settings which hopefully paves the way for entering new markets. Maxivent EC was released 2023.

Full Bachelor Thesis is available in Swedish »Here«

More information about the released Maxivent EC »Here«